Commercial Kitchen Grills: Why Alpha Grill by Aniai Beats Garland and Taylor

The Evolution of Commercial Clamshell Grills

Commercial grills have come a long way from flat tops and charbroilers. For decades, clamshell grills from brands like Garland and Taylor have been the go-to choice for quick-service restaurants (QSRs) and diners. Their appeal is clear: two-sided cooking halves grill times, boosts throughput, and helps keep up with the breakfast and burger rush.

But the restaurant world has changed. With labor shortages, higher customer expectations, and thin margins, operators need more than just heat; they need speed, consistency, and ROI from day one. That’s where the conversation shifts.

The ROI Lens: What Operators Care About Most

Labor Shortages and Turnover: Hiring and retaining skilled kitchen staff is harder than ever. Grills that demand constant oversight or steep training curves add friction to an already strained labor pool.

Throughput and Consistency: Every second counts during peak hours. And every customer expects their burger to taste the same, no matter who’s on shift. Inconsistencies erode brand trust and slow down order flow.

Maintenance and Downtime: Traditional grills often come with complex maintenance needs. When downtime hits, operators pay twice lost sales and repair bills.

Garland vs. Taylor: The Legacy Leaders

Garland Strengths and Weaknesses

Garland clamshell grills have earned a reputation for durability and precision. Operators appreciate their precise temperature controls, touchscreen programming, and ability to handle a range of proteins beyond burgers. For kitchens with dedicated staff on the line, they can be a reliable workhorse.

But the tradeoffs are clear. Cleaning and maintenance are time-intensive, often requiring scraping, calibration, and periodic service calls to keep performance consistent. Operators also note that while Garland delivers quality output, it often demands a full-time grill operator meaning labor savings are limited compared to newer automated systems. In high-volume environments where every minute counts, that extra attention can slow down service and drive up costs.

Garland is a solid, well-built option, but one that shines only when you have consistent labor availability and are willing to invest in the ongoing upkeep.

Taylor Strengths and Weaknesses

Taylor clamshell grills are often recognized for their speed and programmable cooking banks, making them a go-to for chains that want to push volume quickly. Their ability to handle burgers and breakfast proteins with automated lid operation is attractive for operators who prioritize throughput.

However, the downsides are widely discussed in the industry. Many operators report a higher-than-average mechanical failure rate, with components wearing down faster than expected. Cleaning is another challenge: grease buildup and complex disassembly make daily upkeep a burden for staff. On forums like Reddit, operators have shared blunt feedback one noting, “The mechanical failure rate is super high. Difficult to clean… staff avoid using it when they can.”

Taylor promises speed but often delivers unplanned downtime and higher maintenance costs, making it a riskier bet for operators who can’t afford interruptions during peak hours.

Enter Alpha Grill: Next-Gen Efficiency for Modern Kitchens

The Aniai Alpha Grill takes everything operators expect from a commercial clamshell grill and pushes it forward with automation and AI-driven efficiency.

Automated Precision

With recipe-locked presets, every patty is cooked exactly the way you want it - crispy, juicy, and consistent according to the programmed recipe. No guesswork, no wasted product, and no variability between shifts.

The Alpha Grill allows chefs and operators to store unlimited recipes with customizable options, including with‑cheese and without‑cheese modes. Operators can fine‑tune patty thickness, sear settings, and precise cook temperatures for beef, chicken, turkey, plant‑based, or breakfast proteins. This ensures menu flexibility while maintaining consistency across high‑volume service.

Control and programming are managed through an intuitive touchscreen interface, reducing training time and making kitchen operations more streamlined. A line cook simply selects the recipe profile and lets Alpha Grill handle the rest, delivering repeatable results at scale. In foodservice terms, this means reduced food waste, tighter yield control, and consistent cook quality - all critical for QSR and commercial kitchen operations.

Reduced Labor Dependence

By automating the hardest part of line cooking, Alpha frees staff to focus on customers, speed of service, and quality checks. The line cook is no longer tethered to the grill, constantly flipping patties or monitoring cook times. Instead, they place raw patties on the grill, walk away to handle other tasks—whether it’s prepping toppings, restocking the line, or serving guests—and return to perfectly cooked patties ready in the warming tray.

Even better, Alpha eliminates the heavy lifting and repetitive strain that comes with scraping, scooping, and scrubbing a hot grill surface. This not only improves kitchen safety and reduces burnout, but also means fewer staff can manage the same rush with ease. In short, Alpha turns one of the most demanding stations in the kitchen into one of the most efficient.

ROI from Day One

Alpha Grill delivers immediate savings: reduced labor costs, fewer cooking errors, faster throughput, and energy efficiency. Operators see the payback not in years, but in months.

On average, QSRs running the Alpha Grill report 20–30% labor reduction on the grill line. Energy consumption is also lower compared to legacy clamshells, leading to 10–15% savings on utility bills. Faster throughput means more tickets cleared per hour; some locations see higher output during rush periods without adding extra staff.

When all factors are combined - time, labor, energy, and reduced food waste the Alpha Grill often delivers full ROI in under 12 months, thereafter margins are no longer thin thanks to all the savings and profitable for restaurant owners.

Operator Stories

At The Filling Station in West Haverstraw, NY, the Alpha Grill transformed their kitchen workflow. Cook times dropped from 8 mins to just 3 mins not only for burgers but also for grilled chicken. That time savings allowed the same team to push through more tickets per hour without adding staff.

The results were clear: consistently perfect patties, less stress on the line, and faster service at the counter. Customers noticed the difference as takeout orders moved quicker, wait times shrank, and repeat visits grew. In short, Alpha Grill helped the Filling Station serve more guests, more efficiently, while raising customer satisfaction.

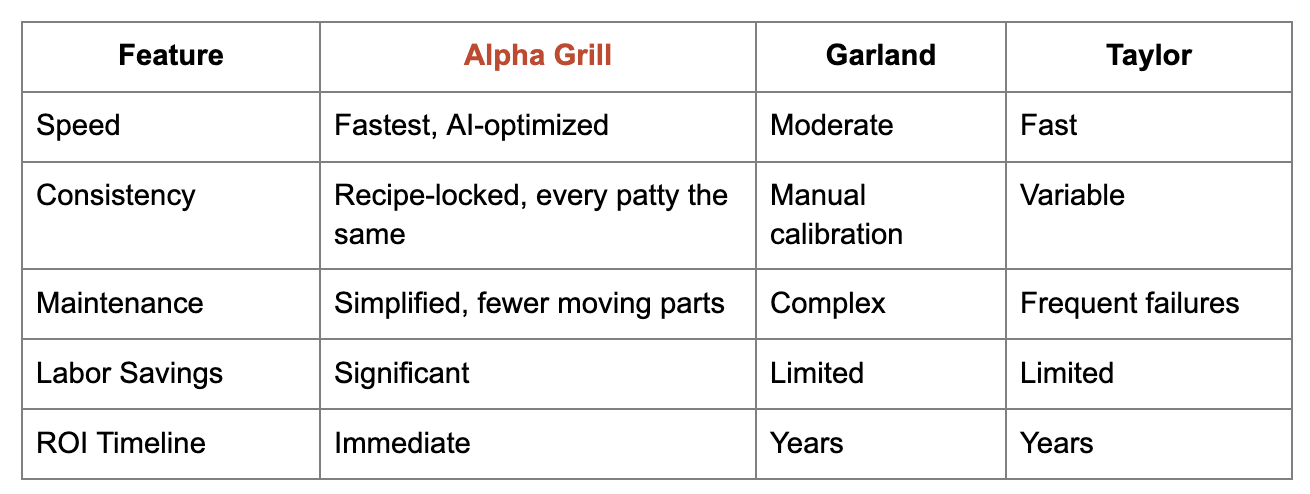

Side-by-Side Comparison: Garland vs. Taylor vs. Alpha Grill

The Future of Grilling: Why Innovation Matters

Why should AI only be for software? Restaurants deserve innovation too.

With equipment like the Alpha Grill, operators can tap into a new era where automation ensures consistency, speed drives throughput, and kitchens run leaner without sacrificing quality. Customers notice the difference immediately: burgers and chicken that arrive hotter, faster, and exactly the same every time.

For operators, it’s more than convenience, it’s survival. Lower costs, higher output, and less staff strain aren’t just nice-to-haves, they’re competitive advantages. As the foodservice industry evolves, embracing technology isn’t about replacing people, it's about empowering them with tools that keep restaurants profitable and customers coming back.

Final Takeaway

Garland and Taylor have served operators well for decades. But in a world where efficiency is survival, the Aniai Alpha Grill delivers something new: automation, consistency, and ROI from day one. Don’t just buy a grill. Invest in the future of your kitchen.

Alpha Grill wins on the metrics operators actually feel every shift throughput, consistency, labor, and total cost of ownership.

Faster, more repeatable output: 8 patties in 2–3 minutes programmed to your specs means reliable speed during lunch and late‑night rushes.

Labor leverage: One operator can load, walk away, and return to finished product freeing minutes every cycle for service, expo, or prep.

Lower waste, tighter margins: Recipe‑locked cooking reduces misfires and overcooks; more sellable patties per box.

Fewer pain points: Less scraping, less hovering, fewer mid‑rush breakdown headaches.

Quicker payback: Combined savings (labor + waste + energy) plus